Machinist's Hammer

More Random 21 Mar 2015

Inspired by the Paulding Hammer my friend Michael and I decided it would be a fun project to make our own machinist’s hammers. Here I’ll cover the design and manufacturing plan.

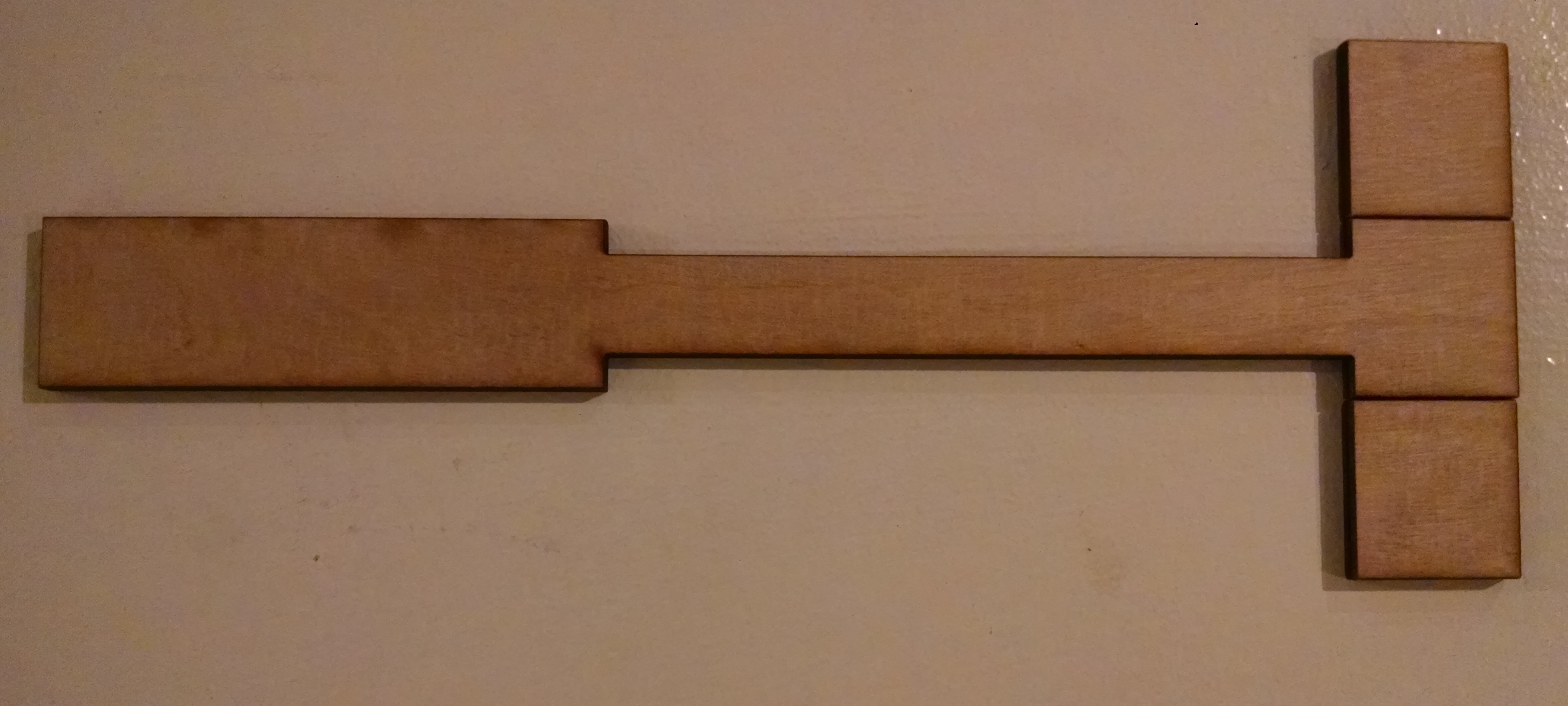

The first photo is of a laser cut mock-up of the hammer to get a feel for the handle size. The hammer will have a knurled handle that is shrink fit into the head of the hammer. The handle will be 6061 aluminum, and the head will be 4130 cromoly steel. We will also make 4 faces for each hammer: 4130 cromoly, C360 brass, 2024 aluminum, and extruded nylon.

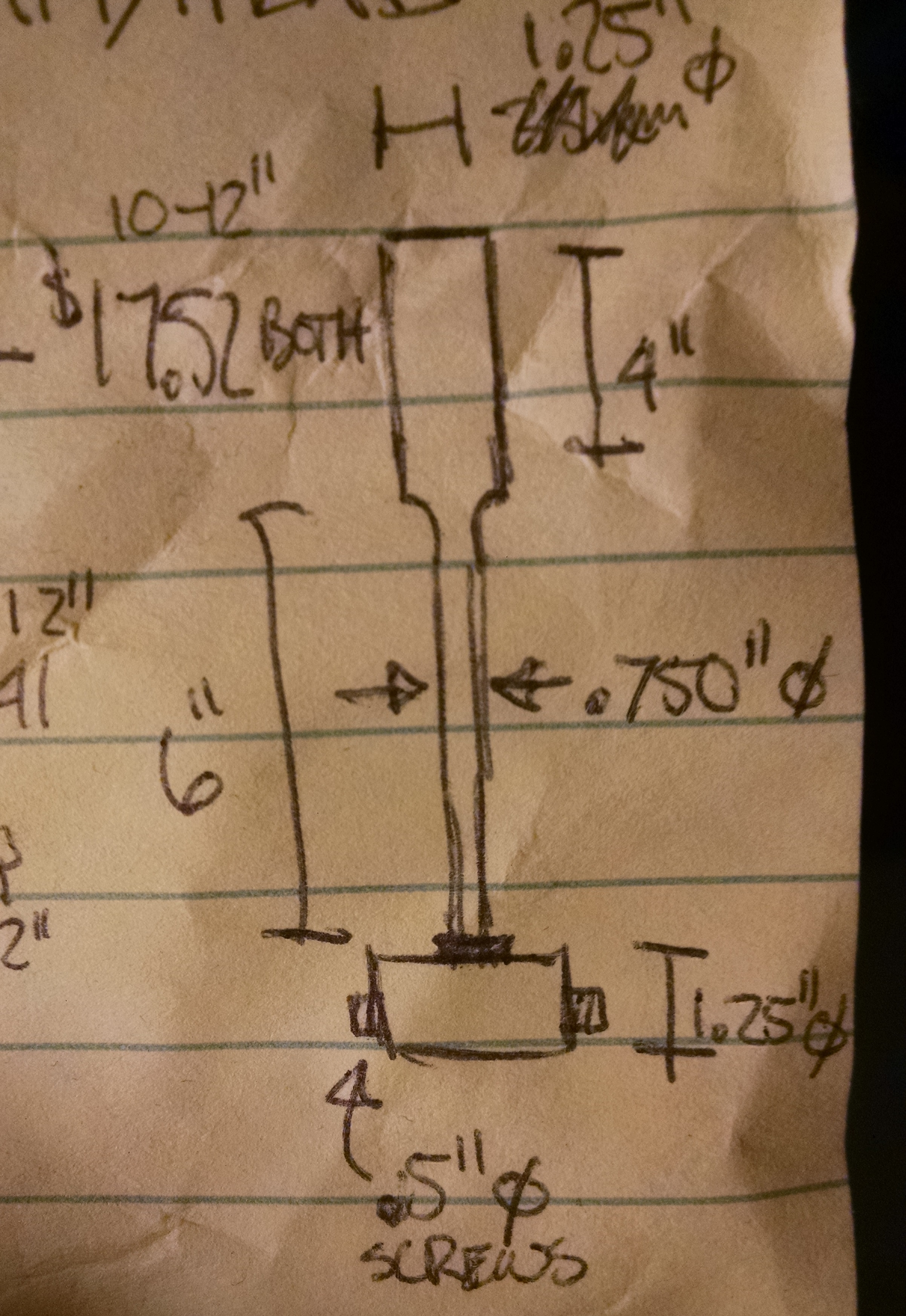

Here is an original sketch of the dimensions of the hammer. They were selected to roughly match the stock diameters and lengths of metals available. Some of them have changed for the final part, but I’ll talk about that in a later post. Since bar stock comes in a minimum length of 12”, this meant that we needed to make 9 hammers to use it all up. This helps spread out the cost, giving you 9 hammers at a material cost of about $20 each. If we each keep a hammer, and each give one away, we can sell the remaining five for $35 or $40 dollars and cover all our costs.

This is the set screw that will attach the faces to the head. Not too exciting I know, but I needed a picture. We’ve worked out a little plan on our processes so we can rapidly make all 9 hammers over a day or two. I’ll post more as we actually manufacture the hammers about what our process turned out to be as we test it on the prototype hammers.

I’m also working on a little laser cut case for each hammer and it’s faces. I’ll write up a post on it later, after I finish the design.